In the manufacturing sectors reliant on durable, corrosion-resistant components—from chemical processing and marine engineering to medical devices and food production—stainless steel stands as a material of choice. Its inherent resistance to rust, oxidation, and chemical degradation makes it indispensable for critical applications, but processing stainless steel into precise, functional parts requires specialized techniques. IO forming machines have emerged as the ideal solution for stainless steel tube and component forming, offering the precision, control, and adaptability needed to preserve the material’s corrosion-resistant properties. When paired with targeted processing strategies, these advanced machines ensure that stainless steel components maintain their structural integrity and longevity—even in harsh operating environments.

Stainless steel’s unique composition—primarily iron, chromium, and nickel—creates a passive oxide layer that shields it from corrosion. However, this layer is vulnerable to damage during forming processes, such as excessive heat, mechanical abrasion, or contamination. Traditional forming methods often risk compromising this protective layer through inconsistent force application, inadequate tooling, or improper lubrication, leading to localized corrosion or reduced durability. IO forming machines address these risks through intelligent process control, delivering the gentle yet precise forming action required to protect stainless steel’s passive layer while achieving tight dimensional tolerances.

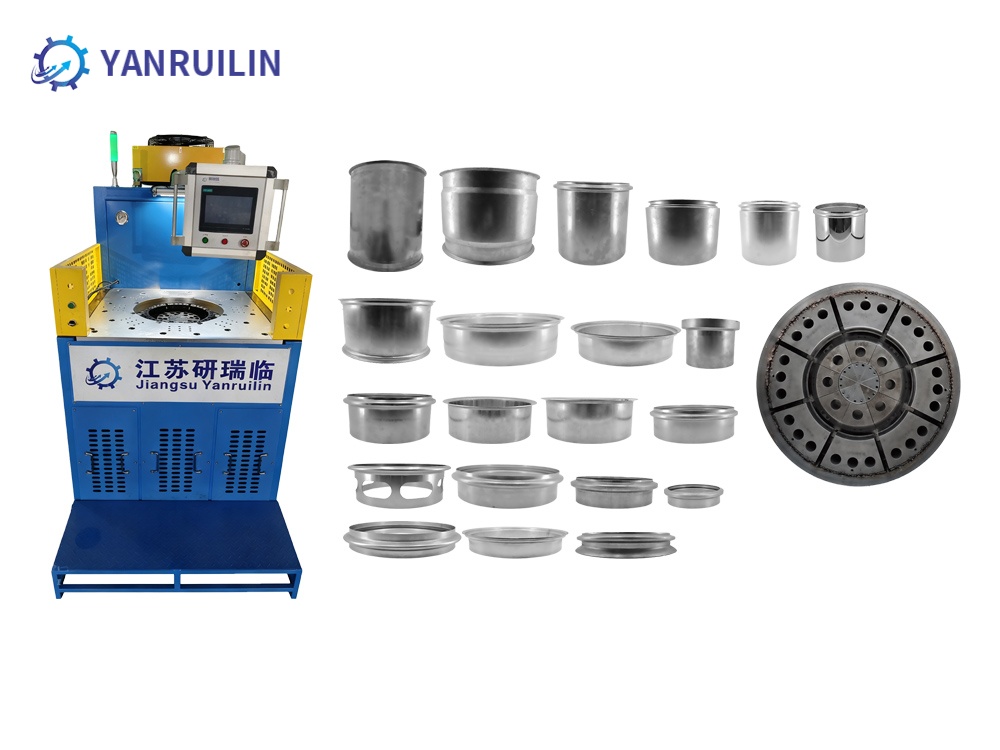

Key Processing Tips for Corrosion-Resistant Stainless Steel Forming

Precision Force and Speed Calibration

Stainless steel’s higher tensile strength and lower ductility compared to carbon steel or aluminum demand tailored forming parameters. IO forming machines’ servo-driven systems and CNC integration allow for precise adjustment of force and forming speed, avoiding excessive stress that can crack the passive oxide layer. Slow, controlled forming sequences—especially for thick-walled stainless steel tubes—distribute pressure evenly, preventing wall thinning or material deformation that creates corrosion-prone weak points. Real-time force monitoring features in IO machines automatically adjust parameters to compensate for material variations, ensuring consistent results across production runs.

Corrosion-Resistant Tooling Selection

Tooling materials play a critical role in preserving stainless steel’s corrosion resistance. Using tooling made from hardened steel, tungsten carbide, or ceramic-coated alloys prevents metal-to-metal contamination—common when carbon steel tools leave microscopic particles on stainless steel surfaces, triggering galvanic corrosion. IO forming machines support quick-change tooling systems, allowing operators to switch to dedicated stainless steel-compatible tooling without downtime. Additionally, tooling should be regularly cleaned and polished to remove debris or oxidation, as accumulated particles can scratch the stainless steel surface and compromise the passive layer.

Lubrication and Cleaning Protocols

Lubrication is essential to reduce friction during forming, but using the wrong lubricant can introduce contaminants that degrade stainless steel’s corrosion resistance. Water-based, chlorine-free lubricants or food-grade mineral oils are ideal, as they avoid leaving residue that traps moisture or chemicals. IO forming machines often integrate automated lubrication systems that apply precise amounts of lubricant to the tooling and tube surface, ensuring uniform coverage without excess. Post-forming, thorough cleaning with a mild alkaline solution or stainless steel-specific cleaner removes lubricant residue, fingerprints, or debris—critical steps to prevent crevice corrosion in formed profiles where contaminants can accumulate.

Avoiding Heat-Related Damage

Excessive heat generated during forming can degrade stainless steel’s passive layer and alter its metallurgical properties, reducing corrosion resistance. IO forming machines minimize heat buildup through efficient force distribution and servo-driven motion, avoiding the friction-induced heat common in mechanical forming. For high-stress forming tasks, intermittent forming cycles or cooling breaks prevent temperature spikes above 200°C—thresholds where the passive layer begins to break down. Additionally, IO machines’ real-time temperature monitoring features (when equipped) alert operators to abnormal heat levels, allowing for immediate parameter adjustments.

Post-Forming Passivation or Pickling

For applications in highly corrosive environments, post-forming passivation or pickling enhances stainless steel’s corrosion resistance. Passivation—typically using a nitric acid solution—restores and strengthens the passive oxide layer, while pickling removes any surface scale or iron contamination from forming. IO forming machines’ precise forming reduces the need for aggressive post-processing, but combining their use with these treatments ensures maximum corrosion protection. Operators should ensure parts are thoroughly rinsed and dried after passivation/pickling to prevent solution residue from causing further damage.

The Advantage of IO Forming Machines for Stainless Steel

Beyond these targeted tips, IO forming machines offer inherent advantages that support corrosion-resistant stainless steel processing. Their ability to execute complex forming sequences in a single pass reduces material handling, minimizing the risk of surface scratches or contamination. IoT connectivity and data logging features allow for traceability of forming parameters, ensuring compliance with industry standards for corrosion-resistant components . Additionally, IO machines’ compact, energy-efficient design reduces operational costs while delivering the precision required for stainless steel’s demanding forming needs.

For manufacturers working with stainless steel, the combination of IO forming machines and corrosion-resistant processing practices is a game-changer. By protecting the material’s passive layer, minimizing contamination, and ensuring precise forming, these strategies extend component lifespan, reduce maintenance costs, and enhance performance in harsh environments. As industries continue to demand durable, corrosion-resistant solutions, IO forming machines—paired with best processing practices—will remain essential for unlocking the full potential of stainless steel in critical applications.

In summary, processing stainless steel for corrosion resistance requires a balance of precision, material awareness, and specialized techniques. IO forming machines provide the intelligent control and adaptability needed to meet these demands, while the tips outlined above ensure that the material’s inherent durability is preserved throughout the forming process. For manufacturers seeking to produce high-quality, long-lasting stainless steel components, this combination is the key to success in a wide range of industries—proving that advanced technology and careful process design go hand in hand to deliver corrosion-resistant excellence.

Este sitio web utiliza cookies para garantizar que obtenga la mejor experiencia en nuestro sitio web.

Comentario

(0)